Product Overview

Product Description

Bi-Metal Hole Saws

HSS hole saws made of shatter-proof and tough HSS bimetal are used on drilling machines and hand-held drills.

Advantages:

- Cost-effective sawing of round cut-outs

- Can be used on diverse materials such as alloyed and non-alloyed steels, stainless steel (INOX), aluminium, copper, bronze, brass, wood, plastics etc. (please observe the recommendations for use on stainless steel)

- Chattering during sawing is prevented by an alternating tooth pitch of the hole saw

- A selection of the most common HSS hole saws in sets for tradesmen, fitters, electricians and mechanics

- The hole saws are centred and guided via the HSS pilot drill (supplied with compression spring for improved ejection of the sawn material)

Recommendations for use:

- Clamp the pilot drill in the hole saw arbor and make sure that it projects at least 3 mm (1/8") over the teeth of the hole saw.

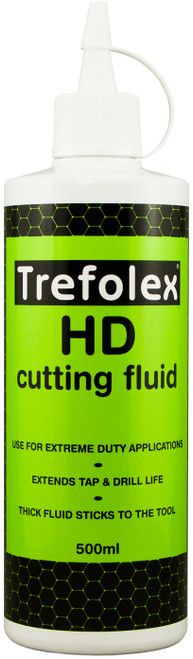

- When cutting metals, use a high-quality cutt ing oil, if possible. This facilitates smooth running and lengthens the hole saw life. Exceptions: When working on aluminium, use kerosene instead of cutting oil.

- HSS hole saws are suitable for work on stainless steel (INOX). Remove any particles which develop during use from the

workpiece in order to avoid corrosion. Clean the workpiece chemically or mechanically (etching/polishing, etc.).

- Make sure that all the teeth are applied evenly. Avoid swinging movements during sawing to prevent tooth breakage.

- Avoid overheating.

Safety notes:

When using shank extensions, the recommended

hole saw rotational speed must not

be exceeded.

HSS hole saws made of shatter-proof and tough HSS bimetal are used on drilling machines and hand-held drills.

Advantages:

- Cost-effective sawing of round cut-outs

- Can be used on diverse materials such as alloyed and non-alloyed steels, stainless steel (INOX), aluminium, copper, bronze, brass, wood, plastics etc. (please observe the recommendations for use on stainless steel)

- Chattering during sawing is prevented by an alternating tooth pitch of the hole saw

- A selection of the most common HSS hole saws in sets for tradesmen, fitters, electricians and mechanics

- The hole saws are centred and guided via the HSS pilot drill (supplied with compression spring for improved ejection of the sawn material)

Recommendations for use:

- Clamp the pilot drill in the hole saw arbor and make sure that it projects at least 3 mm (1/8") over the teeth of the hole saw.

- When cutting metals, use a high-quality cutt ing oil, if possible. This facilitates smooth running and lengthens the hole saw life. Exceptions: When working on aluminium, use kerosene instead of cutting oil.

- HSS hole saws are suitable for work on stainless steel (INOX). Remove any particles which develop during use from the

workpiece in order to avoid corrosion. Clean the workpiece chemically or mechanically (etching/polishing, etc.).

- Make sure that all the teeth are applied evenly. Avoid swinging movements during sawing to prevent tooth breakage.

- Avoid overheating.

Safety notes:

When using shank extensions, the recommended

hole saw rotational speed must not

be exceeded.